Material Matters: 3D-Printed Sneakers

3D printing, aka additive manufacturing, dates all the way back to the 1970s, but its prevalence in footwear has only emerged in the past decade. While still very much in its conceptual phase and yet to be adopted mass market, the technology will only become more commonplace as brands continue to dabble in it. Here’s a quick rundown of how it’s being used in sneakers.

Tech Talk

As its name suggests, 3D printing means the media is being printed in three planes as opposed to the flat two of ‘traditional’ 2D. Its alternative name of additive manufacturing is perhaps a more accurate definition of the technique, as material is being added to itself or other surfaces to build objects.

There are various broad categories of additive manufacturing, such as material extrusion and light polymerisation. These are two of the most common techniques used for 3D-printed shoes, with some manufacturers developing proprietary machinery and/or methods.

As far as materials go, thermoplastic reigns supreme for printed footwear. Thermoplastic polyurethane has been used for sneaker parts – think external counters, lace cages and midsole foam, for example – for decades, so it continues to be an ideal composition. As fused filament fabrication aka fused deposition modelling is a common method to print shoes, TPU serves as the best matter to use to manufacture a shoe from one material.

Pros and Cons

One of the major advantages of 3D printing at large is the ability to quickly prototype or manufacture a complex design, compared to more traditional techniques like CNC machining and investment casting. A sample can in theory be turned from a sketch into physical object within a day, and timeframes grow shorter as the tech matures. Another major consideration is precise print designs means minimal, if not near-zero, waste is produced, as production doesn’t have to deal with offcuts and scrap material.

The main crux preventing 3D printing from reaching mainstream prevalence at this stage is the comparatively slow rate at which shoes and their parts can be printed. Human and machine-machine-assisted production line labour are reportedly manufacturing over 23 billion pairs of shoes each year. It’ll be a while before the printers catch up.

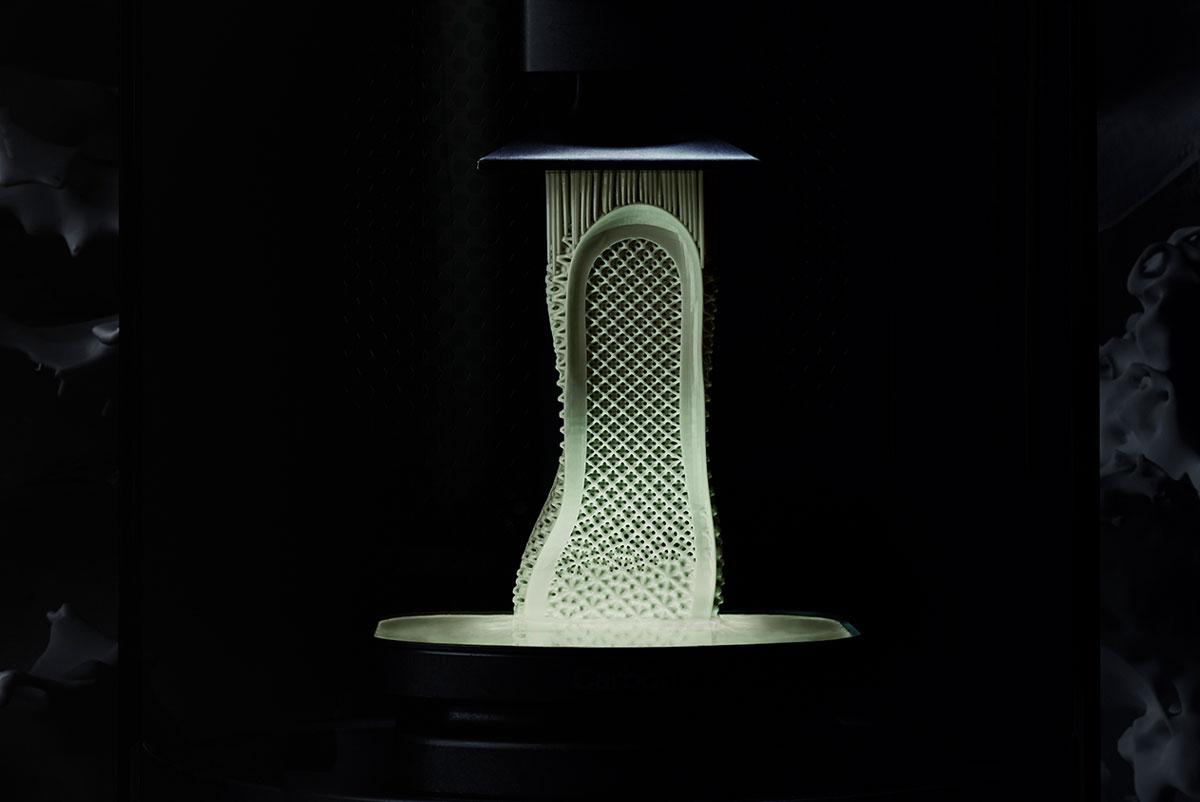

In 2017, and California-based company Carbon teamed up to begin manufacturing midsoles using the latter’s ‘Digital Light Synthesis’ technique. In layman’s terms, DLS passes UV light images of the part (in this case, the 4D midsole) through a ‘light window’ onto liquid resin, causing the part to partially cure as more of it is ‘printed’. A thin layer of oxygen about one third the thickness of human hair between the window and the part allows more liquid resin to flow to the base of the part and continue being formed by the UV light. A secondary thermal curing process then gives the part enough strength for real-world use. DLS seems to be manufacturing the highest volume of printed footwear at a fast rate with pretty consistent results. As such, the Three Stripes remain committed to 4D tech as they currently offer over 35 different colourways across multiple models.